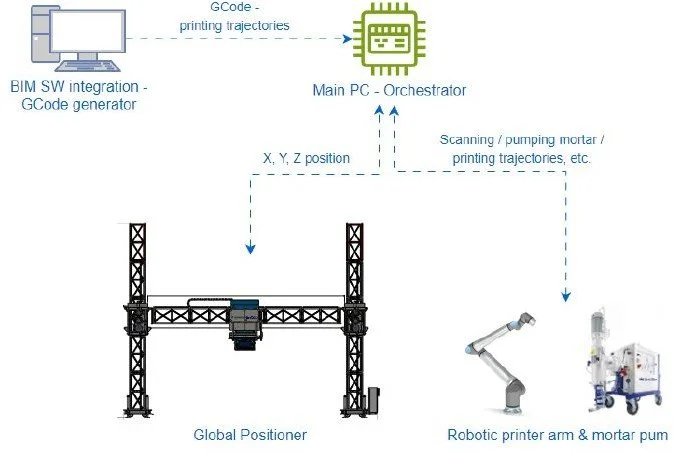

In INPERSO’s 3D Printing façade System, four organizations participate. UPV and CARTIF develop the 3d printing subsystem, integrated into an industrial robot arm (print head and control) offering a cutting-edge solution for the renovation of building facades. ITA develops the Global position subsystem which is a part of the Façade 3D printing, and VIAS provides the robotic system for the 3d printing.

Robotic, vertical façade 3D printer integration

Define system requirements and conceptual design

Develop and detail the prototype design

Manufacture, test, and integrate subsystems

Commission and validate the integrated system

This innovative system provides customized solutions tailored to the specific needs of each case. It not only ensures increased safety for workers but also introduces flexibility and material savings in the façade renovation process.

The INPERSO façade printing system fully applies robotics and 3D printing technology to refurbishment works on building exteriors.

The system autonomously prints vertical surfaces using a digital model of the building, ensuring precise movements and material placement while avoiding damage to the environment or people.

This integration of new technologies with modified traditional machinery will reduces labour risks, execution time, environmental impact, and economic costs. The system consists of a 3D printing subsystem with a prototype extrusion head on an industrial robotic arm, a global positioning subsystem with a motorized scaffold platform, a safety subsystem with robotic perception sensors, BIM integration software, a mobile concrete pump, and a power generator to supply energy to the subsystems.

Work carried out

Global positioner

The Global Positioner moves the Robotic Printer Arm along the X, Y, and Z axes using three motorised trolleys with rack-and-pinion mechanisms for precise façade positioning

Stability and precision were achieved through a robust displacement system inspired by mast climbing work platforms

Iterative FEM analyses ensured structural stiffness and evaluated system scalability, particularly along the X axis

Robotic printer & printable materials

UR20 robot, material pump, and an industrial PC were integrated as the main system

The setup ensured full connectivity and control through preliminary subsystem tests

The Flow-Matic extruder with dual cameras enabled remote monitoring via 3D-printed mounts

Webots simulations modelled and tested subsystem and full-system performance

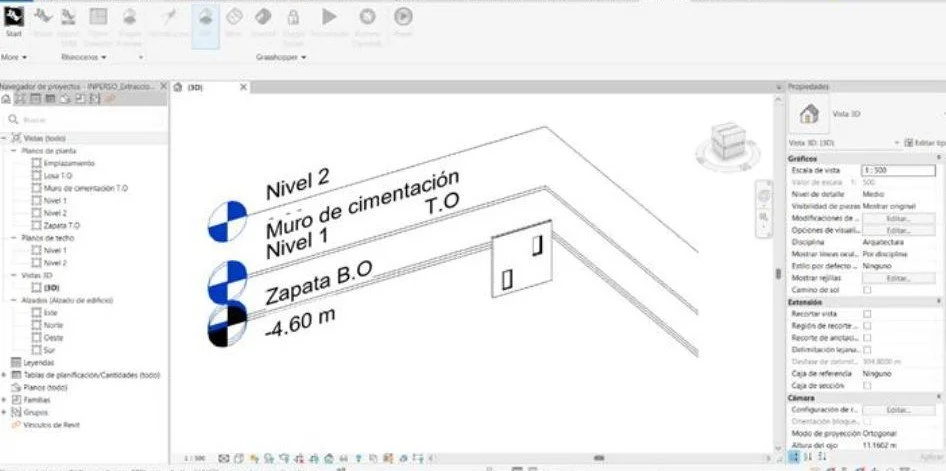

Software for BIM-CAM integration

Segregation into smaller áreas for better definition of trajectories

Trajectories definition that aim for the shortest time and best adherence and surface quality

Openings conditions consideration

Printing process

Laboratory tests carried out for controlled printing areas conditions

Thickness variation ensuring the best possible execution and waste reduction

The aim is to perform with little human assistance